According to the international standard organization's definition, container as a transportation equipment, should meet the following requirements: (1) has the durability, strong enough to use repeatedly; (2) is for convenience of goods transport and special design, in one or DuoZhong mode of transportation transportation in without midway outfit; (3) a easy to assemble and unassemble and, especially from the device for a way to transfer to another transportation mode of transportation; (4) the design should facilitate full discharge the goods and empty; (5) content product for 1 m + 3 or more than 3 m + 1.

The advantages of container transportation mainly lies in: (1) container can be used repeatedly, simplify the packaging of goods, saved a lot of packing charge; (2) reduce damage, improve the quality of the goods sent freight container, because is a strong sealed box, the goods shipped, no damage and reduce the existing goods sent to the waste of material wealth, increase the economic efficiency and the social efficiency; (3) reduce the operating cost, reduce the transportation cost. Because container loading and unloading high efficiency and weather, improve the ship and port of loading and unloading rate, so as to enhance the benefits.

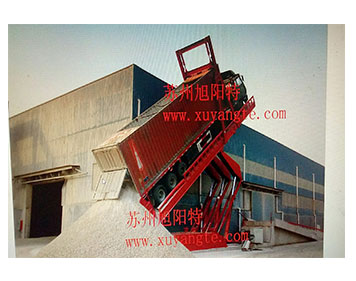

Now the common container bulk material packing has two methods: artificial shovel dug and using belt conveyor. The common container bulk material unloading have two kinds of methods, one kind is container from semi-trailer commit suicide by hanging to the ground, with artificial or mechanical equipment into the box and dig, unloading time long, low efficiency; Another kind is to use one end of the container crane, the other side position unchanged, form, make the bulk material Angle free fall. These two methods require equipped with large hoisting equipment, is restricted by bulk material container transportation logistics mode the technical bottleneck problems, in order to solve this problem, we design the bottleneck container bulk material tipping device.

中文 |

中文 | En

En

苏公网安备32050702010649号

苏公网安备32050702010649号